Vertical Casting Machines

Vertical centrifugal casting machinery spins parts about a vertical axis. Parts are commonly of shorter height than diameter. The great benefit of spinning about a vertical axis is that practically any size and shape of casting can be spun about a vertical axis. Common castings poured in vertical machinery are rings and ball valve balls. Generally, vertical machines are divided into two categories, Stand-Alone machines, which can be easily added into a foundry with limited foundation work and Pit Mounted machinery, which are mounted below floor level and require a foundry to do substantial foundation work.

The question commonly asked is, can a casting that is commonly poured statically be poured vertically, even if it is a nonstandard shape. The answer is yes. Why pour castings in a vertical spinning machine that can be poured statically? The primary reasons are to obtain better quality castings, to produce castings more economically and to cast a part that cannot be satisfactorily cast statically. Reduction in cleaning room costs and higher yield are common reasons why foundries pour castings using vertical centrifugal casting machinery. Steel castings that are statically poured with a yield of 40 to 55% can be centrifugally cast with a yield closer to between 65 and 85%.

|

Shop Floor Ready MachinesThe VP series of centrifugal casting machines are designed for the foundry environment. Heavy duty main frame designs with counter-weighted covers comes complete with variable speed drive units, drive controller and operators controls. Mold cooling and heating manifolds are mounted and comes complete with air/gas mixing tee and electrically controlled solenoid water valve. Mold adapter table and centering boss are assembled and ready for molds. Models JA, AVB, VP500, VP1000, VP1200 |

| Model | Casting Size Maximum OD | Casting Height Maximum | Maximum Load | |||||

|---|---|---|---|---|---|---|---|---|

| Imperial | Metric | Imperial. | Metric | Imperial | Metric | |||

| JA Request Quote | - | - | 18" | 610mm | 8" | 203mm | 500lbs | 227kgs |

| VP1000 Request Quote | - | - | 20" | 508mm | 12" | 305mm | 1,000lbs | 454kgs |

| VP1200 Request Quote | - | - | 22" | 560mm | 13" | 330mm | 1,200lbs | 544kgs |

| VP1500 Request Quote | - | - | 24" | 610mm | 21" | 533mm | 1,500lbs | 680kgs |

| Load Ratings are based on the combined weight of fixtures and bearing shell. | ||||||||

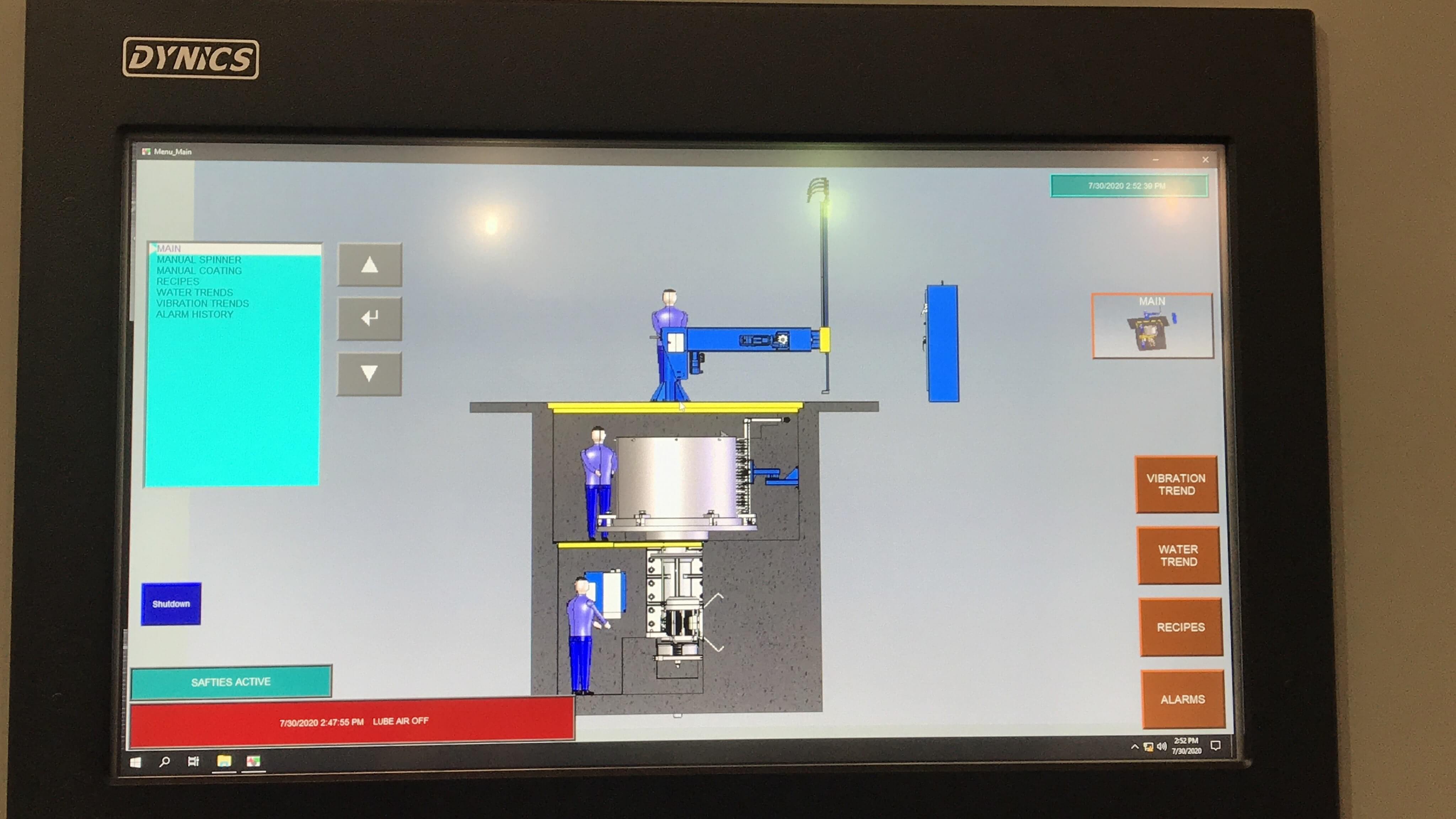

Pit Mounted Machines

CCMCO's Pit Mounted series of equipment is designed and built for a rugged foundry environment. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest degree of casting configurations and are capable of producing True Centrifugal, Semi-Centrifugal and Centrifuge or Pressure castings, pouring both ferrous and non-ferrous materials.

Machines are composed primarily of:

- Spinner Assembly

- Lubrication System

- Mold Water Cooling Assembly

- Shaft Cooling Assembly

- Pouring Funnel

- Adapter Table

- Main Control Cabinet with Variable Speed Drive Unit

Popular products produced on these machines include:

- Pulverizer Rolls

- Steel Mill Rolls

- Ball Valve Rolls

- Forming Rolls

- Sleeves

- Non-Cylindrical Geometries

Pit Mounted Machines

| Model | Maximum Mold Diameter | Maximum Mold Height | Maximum Balanced Load | |||||

|---|---|---|---|---|---|---|---|---|

| Imperial | Metric | Imperial | Metric | Imperial | Metric | |||

| A Request Quote |

- | - | 36" | 915mm | 30" | 760mm | 1,200lbs | 544kgs |

| C Request Quote |

- | - | 60" | 1,525mm | 36" | 915mm | 5,000lbs | 2,270kgs |

| D Request Quote |

- | - | 72" | 1,829mm | 45" | 1,143mm | 10,000lbs | 4,535kgs |

| G Request Quote |

- | - | 80" | 2,032mm | 50" | 1,270mm | 20,000lbs | 9,070kgs |

| VSC Request Quote |

- | - | 114" | 2,895mm | 60" | 1,524mm | 30,000lbs | 13,605kgs |

| VF Request Quote |

- | - | 114" | 2,895mm | 60" | 1,524mm | 50,000lbs | 22,680kgs |

| VH Request Quote |

- | - | 114" | 2,895mm | 60" | 1,524mm | 75,000lbs | 34,020kgs |